Is Your Heat Treatment System Treating the Atmosphere Badly?

The Project

There was awareness that releasing 1700°F (925°C) of combustion product up a stack provided for significant heat recovery and energy savings opportunities. This Continuous Heat Treat operation line consisted of a Hardening and Draw Furnace that ran at high temperatures yet it did not implement any heat recovery technology.

A natural gas consumption baseline was developed to benchmark current furnace operating efficiencies. Energy saving strategies and priorities were determined through a systematic analysis of the existing equipment.

Diagnosis and Findings:

- Poor control of Draw Furnace pressure

- Potential annual savings over 7 million cubic feet of natural gas on the High Heat/Draw Furnace

- Total energy savings identified by the audit was projected at $110,000 on an annualized basis

“From waste heat to 7 million cubic feet of natural gas savings shows that hiring the experts will save you thousands in energy costs within a few years payback!”

– Russ Chapman, President, Firebridge Inc., 2019

The Firebridge Solution

Using the Six Delta™ Method to gain an optimised perspective, Firebridge identified several performance improvement opportunities. The Six Delta™ Method is a comprehensive approach through a systematic analysis which considers improvements over six interdependent focus areas. This method is data driven by metrics from each focus area which combine to drive a strong business case.

The Six Delta™ focus areas for this project are:

Primary: Energy Consumption – Product Quality – Process Production – GHGe Emissions

Secondary: Safety & Compliance – Equipment Reliability

Solutions Implemented:

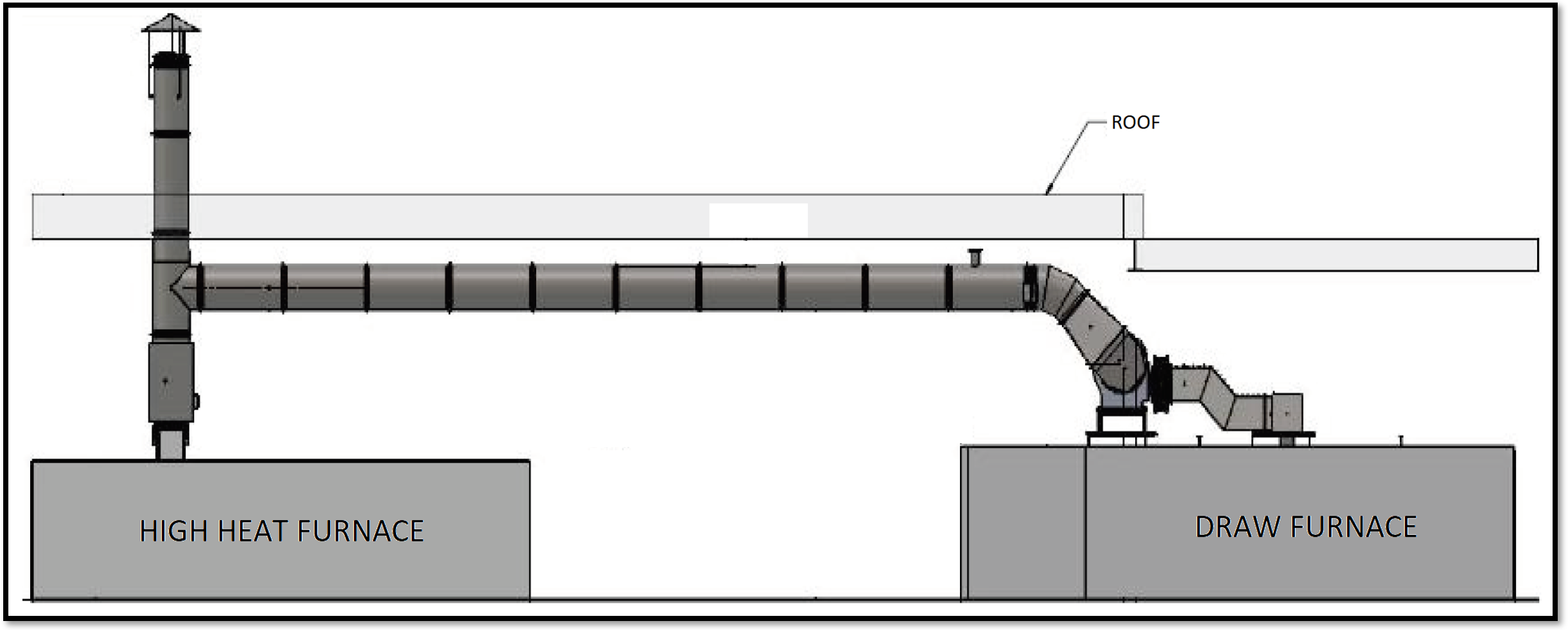

A case was made to capture the waste heat generated by the Hardening Furnace and use it to heat the Draw Furnace.

- Provided the engineering, procurement, construction, and system commissioning to redirect 1700°F flue gases from the Hardening Furnace to the Draw Furnace

- Eliminate the need to dilute the exhaust with inside air, reducing the local exhaust by 1,700 SCFM

- Ducts and fan sized to minimize the negative pressure in the High Heat Furnace

- Provided internally insulated duct work to eliminate thermal expansion issues

![]()

Improved results were found across all Six Delta™ focus areas.

Safety & Compliance

- New system meets current safety and compliance standards

Quality

- Improve the cold air leaking into the High Heat Furnace by sealing

Productivity

- Installation and commissioning during summer shut-down

- Total payback period 1.8 years

Energy Consumption

- Fuel consumption was reduced by 31% on the Draw Furnace

Reliability

- Minimized negative pressure in the High Heat Furnace

- Internally insulated ducting eliminated thermal expansion issues

Greenhouse Gas Emissions

- GHGe emissions reduced by 31%

Liked what you read? Stay up to date with new content by Subscribing below!